中国科学院微生物研究所,中国微生物学会

文章信息

- 刘东方, 黄建忠, 陶勇, 杨欣伟, 柯崇榕. 2024

- LIU Dongfang, HUANG Jianzhong, TAO Yong, YANG Xinwei, KE Chongrong.

- 吡咯喹啉醌合成及生产工艺研究进展

- Research progress in synthesis and production technology of pyrroloquinoline quinone

- 微生物学报, 64(4): 999-1018

- Acta Microbiologica Sinica, 64(4): 999-1018

-

文章历史

- 收稿日期:2023-10-27

- 网络出版日期:2024-01-31

2. 中国科学院微生物研究所 微生物生理与代谢工程重点实验室, 北京 100101

2. CAS Key Laboratory of Microbial Physiological and Metabolic Engineering, Institute of Microbiology, Chinese Academy of Sciences, Beijing 100101, China

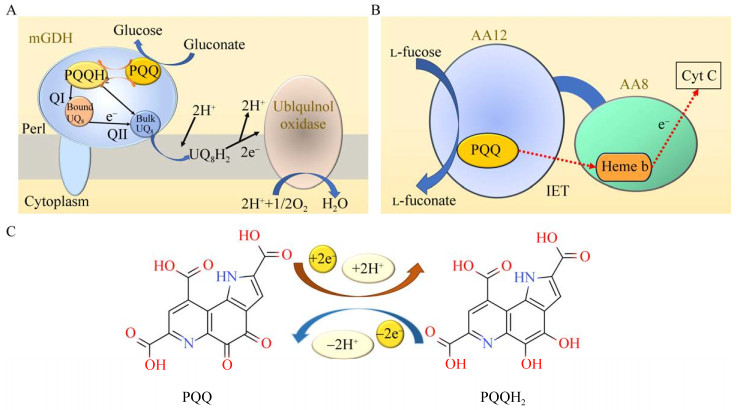

Hauge[1]于1964年发现荧光假单胞菌(Pseudomonas fluorescens)的葡萄糖脱氢酶中存在一类新型的不同于烟酰胺腺嘌呤二核苷酸/烟酰胺腺嘌呤二核苷酸磷酸(nicotinamide adenine dinucleotide/nicotinamide adenine dinucleotide phosphate, NAD+/NADP+)或黄素单核苷酸/黄素腺嘌呤二核苷酸(flavin mononucleotide/flavin adenine dinucleotide, FMN/FAD)的辅因子,1979年Salisbury等[2]从假单胞菌(Pseudomonas sp.)的甲醇脱氢酶中分离出该辅因子并鉴定了其分子结构,命名为吡咯喹啉醌(pyrroloquinoline quinone, PQQ)。PQQ化学式为4, 5-二羰基-1-吡咯-2, 3-f-喹啉-2, 7, 9-三羧酸(图 1),含有3个羧基和吡咯环等官能团,可参与氧化还原和羰基化等生化反应,抗氧化能力是抗坏血酸、甲萘醌等异黄酮类和多酚类化合物的100多倍[3]。PQQ在细菌和真菌中作为甲醇脱氢酶(methanol dehydrogenase, MDH)、葡萄糖脱氢酶(glucose dehydrogenase, GDH)和吡喃糖脱氢酶(pyranose dehydrogenase, PDH)等脱氢酶的辅因子[4-8],以一个较高的氧化还原电势(+90 mV)捕获醇/糖类等底物上的电子,随后将电子传递给受体辅酶Q或细胞色素(B或C) (图 2)[9-12],协助脱氢酶完成特定的催化作用,实现底物的氧化[13]。PQQ通过Mg2+/Ca2+介导的非共价键与酶蛋白结合,单分子循环催化次数可高达20 000次[14],催化过程中PQQ获得电子形成还原态PQQH2,传递电子后又恢复回氧化态PQQ (图 2)[11-12]。

|

| 图 1 PQQ的化学结构图 Figure 1 Chemical structure diagram of PQQ. |

截至目前,PQQ作为发现的唯一存在于所有动植物组织中并参与生长发育的活性小分子,具有促进生长、优化线粒体生物发生、清除自由基、增强细胞代谢和提高抗逆性等生理功能[15-17]。近期研究表明,PQQ还能在缺氧微环境中维持线粒体稳态,保证细胞正常代谢,缓解严重急性呼吸系统综合征冠状病毒2 (severe acute respiratory syndrome coronavirus 2, SARS-CoV-2)综合征[18]。人类自身无法合成PQQ,只能从食物中摄取,芹菜、猕猴桃和纳豆等食物中PQQ含量较高,其中人类母乳中PQQ含量高达140−180 μg/L[19-20]。因此,Nature曾发表评述讨论PQQ是否应归类为维生素[21];Ames教授于2018年在PNAS发文将其定义为“长寿维生素”[22]。美国、欧盟、加拿大、日本和中国已先后批准PQQ·Na2 (PQQ的商品化形式)作为膳食补充剂或新食品原料,中国国家农业农村部和药品监督管理局也先后批准PQQ·Na2作为新饲料添加剂和化妆品新原料[23]。随着市场需求的急剧增长,高产菌株的选育及其高效纯化工艺的开发成为PQQ工业化生产的首要问题。本文主要综述了PQQ化学合成路径、生物合成途径及其调控机制、高产菌株选育及其分离纯化等方面的研究进展,为微生物发酵法工业化生产PQQ提供参考。

1 PQQ的生理功能及应用 1.1 PQQ维持啮齿动物和人类健康PQQ作为细菌和真菌中脱氢酶的辅酶,在啮齿动物和人类中具有重要的生物学功能。首先,PQQ能够增强细胞中神经生长因子(nerve growth factor, NGF)的产生,促进皮层初级神经元的生长发育,改善动物的记忆和认知能力[24]。Yamada等[25]通过被动回避实验发现腹腔注射PQQ·Na2 (5.0 mg/kg-BW, 7 d)的小鼠进入暗室的时间从15 s延长至150 s左右,是对照组(15 s延长至45 s左右)的3.3倍;Tamakoshi等[26]对补充PQQ·Na2 (20 mg/d)的20−65周岁成年人进行了Cognitrax测试,发现连续8周补充PQQ·Na2的受试者(20−40周岁)认知灵活性和执行速度显著提升,连续12周补充PQQ·Na2的受试者(41−65周岁)复合记忆和言语记忆能力明显改善。其次,PQQ具有很强的抗炎和抗氧化能力,能通过缓解细胞的炎症和氧化应激损伤保护机体。Wu等[27]发现PQQ处理的脓毒症大鼠(盲肠结扎穿孔手术前1 h腹腔注射10 mg/kg-PQQ,术后连续2周每天补充10 mg/kg-PQQ)炎症因子白细胞介素(interleukin, IL)-1β、IL-6和肿瘤坏死因子(tumor necrosis factor, TNF)-α水平普遍降低,血清中谷丙转氨酶(alanine transaminase, ALT)、谷草转氨酶(aspartate transaminase, AST)和碱性磷酸酶(alkaline phosphatase, ALP)的浓度降低50%−60%,肝细胞中氧化应激标志物丙二醛(malondialdehyde, MDA)水平下降40%、谷胱甘肽(glutathione, GSH)水平上升65%,肝细胞结节数减少,明显减轻了脓毒症引起的急性肝损伤;Harris等[28]在临床试验中发现补充PQQ (0.3 mg/kg, 3 d)受试者的血浆中C-反应蛋白(c-reactive protein, CRP)和IL-6水平分别下降了45%和30%,硫代巴比妥酸反应物(thiobarbituric acid reactive substances, TBARS)含量显著下调。此外,PQQ能减少机体脂肪的积累,在抗肥胖和预防肥胖及其并发症方面具有积极作用。Nakano等[29]在临床试验中对连续12周补充PQQ·Na2 (20 mg/d)的受试者血液进行分析,发现实验组血清中低密度脂蛋白胆固醇(low-density lipoprotein cholesterol, LDL-C)的水平显著降低。最后,PQQ还可以通过调节胞内包括作用线粒体在内的多种信号通路、调控干扰素(interferon, IFN)-γ和IL-4等炎症因子、生长因子的表达发挥其提高细胞代谢、保护线粒体和保护神经等功能[30]。上述实验结果表明,PQQ在神经退行性疾病、机体损伤及肥胖综合征疾病领域的预防和治疗方面潜力巨大,对维持生物体正常生理功能具有重要的作用。

1.2 PQQ提高经济动物产量PQQ可以提高经济动物的抗氧化能力、线粒体功能并促进生长。在牲畜饲料中添加PQQ可以提高其抗氧化能力,保护牲畜安全。Zhang等[31]在饲料中添加1.5−7.5 mg/kg的PQQ·Na2,显著提高了妊娠期和哺乳期家猪体内超氧化物歧化酶(superoxide dismutase, SOD)、谷胱甘肽过氧化物酶(glutathione peroxidase, GSH-Px)和过氧化氢酶(catalase, CAT)等酶的活性,提升机体的抗氧化能力。家禽饲料中额外添加PQQ·Na2可以提高禽类的线粒体活性、抗氧化能力和肉类品质。Wang等[32-33]在雏鸡饲料中补充PQQ·Na2 (0.2 mg/kg, 42 d)后,鸡的总抗氧化能力(total antioxidant capacity, T-AOC)提高41.3%,料重比(feed to gain ratio, F/G)降低,胸肌平均质量增加;水产养殖中补充PQQ可以促进鱼类生长因子的表达,调节生长激素-胰岛素样生长因子轴(growth hormone insulin-like growth factor axis, GH/IGF),进而促进生长。Shi等[34]在黄颡鱼幼鱼的饲料中添加PQQ (3−6 mg/kg)提高了幼鱼体内生长因子如生长激素(growth hormone, GH)、胰岛素样生长因子(insulin-like growth factor, IGF)-1和IGF-2等的表达量,显著提升了黄颡鱼平均最终体重(final body weight, FBW)、增重率(weight gain rate, WGR)和特定生长率(specific growth rate, SGR)等生长参数,降低料肉比(feed conversion ratio, FCR)。

1.3 PQQ促产并保护经济作物PQQ可以增加土壤中微生物数量、提高有效磷含量和植物叶绿素含量,从而促进植物的生长。李震等[35]对烟草进行灌根或喷施PQQ (200 nmol/L)的处理,植株根鲜重和干重提升9%以上,最大根长、主根数等明显增多,根系活力提高1.4倍以上。朱云集等[36]对孕穗期冬小麦进行喷洒PQQ (50 μmol/L,3次)的处理,5 d后胞内硝酸还原酶(nitrate reductase, NR)和ALT活性上升20%和35%,25 d后叶片叶绿素含量增加15%且光合速率上升25%以上。PQQ还可以预防病害及提高作物的抗逆性。病害防治方面,Li等[37]对水稻Gaopin 6号喷洒1.0 μmol/L的PQQ,144 h后病害严重程度(disease severity, DS)评分0.88,仅为对照组的23%;研究发现,PQQ促进了OsOSM1、OsAOS2、OsHI-LOX和OsLOX1基因的表达,降低了OsWRKY72基因的表达,显著增加了茉莉酸(jasmonic acid, JA)等抗性诱导因子的表达量,提高了预防真菌感染的病害抗性;抗逆方面,何曙光等[38]使用0.5−1.0 μmol/L的PQQ喷洒处于8 ℃低温胁迫条件下的早稻幼苗,幼苗胞内SOD和过氧化物酶(peroxidase, POD)活性提升了9.19%和11.45%,MDA积累显著减少,植株耐冷能力增强,幼苗存活率增加了15%以上。

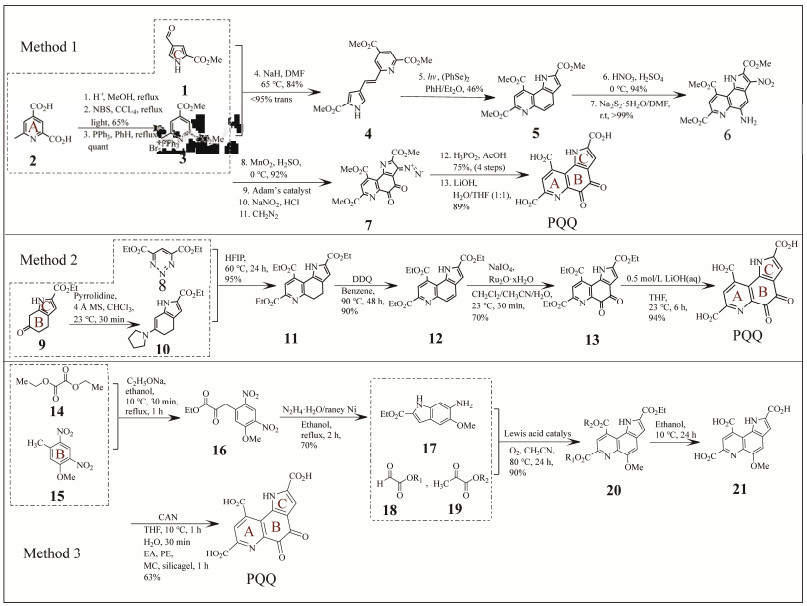

2 PQQ的化学合成PQQ最初在1981年由Gainor等[39]和Corey等[40]分别独立通过收敛法合成。经过40多年的发展,合成工艺已经从十五步法优化至目前的三步法、四步法,产率逐渐自2%上升至56%[41]。根据底物化学结构的差异,PQQ的化学合成法大体分为3类(图 3)[42-44]。

|

| 图 3 化学合成PQQ的三类方法[42-44] Figure 3 Three methods of chemical synthesis of PQQ[42-44]. 1: 5-ethyl-1H-pyrrole-3-carbaldehyde; 2: 6-methylpyridine-2, 4-dicarboxylic acid; 3: Methyl 4-(methoxycarbonyl)pyridine-2-carboxylate (brominated); 4: Methyl 6-(methoxycarbonyl)-2-[(1E)-2-[5-(methoxycarbonyl)-1H-pyrrol-3-yl]vinyl]pyridine-4-carboxylate; 5: Methyl 2, 9-bis(methoxycarbonyl)-1H-pyrrolo[2, 3-f]quinoline-7-carboxylate; 6: Methyl 5-amino-2, 9-bis (methoxycarbonyl)-3-nitro-1H-pyrrolo[2, 3-f]quinoline-7-carboxylate; 7: Trimethyl 3-diazo-4, 5-dioxo-4, 5- dihydro-3H-pyrrolo[2, 3-f]quinoline-2, 7, 9-tricarboxylate; 8: Ethyl 6-(ethoxycarbonyl)-1, 2, 3-triazine-4-carboxylate; 9: Ethyl 6-oxo-4, 5, 6, 7-tetrahydro-1H-indole-2-carboxylate; 10: Ethyl 6-(tetrahydro-1H-pyrrol-1-yl)-4, 5-dihydro- 1H-indole-2-carboxylate; 11: Ethyl 2, 9-bis(ethoxycarbonyl)-4, 5-dihydro-1H-pyrrolo[2, 3-f]quinoline-7-carboxylate; 12: Ethyl 2, 9-bis(ethoxycarbonyl)-1H-pyrrolo[2, 3-f]quinoline-7-carboxylate; 13: Ethyl 2, 9-bis(ethoxycarbonyl)-4, 5- dioxo-4, 5-dihydro-1H-pyrrolo[2, 3-f]quinoline-7-carboxylate; 14: Ethyl 2-ethoxy-2-oxoacetate; 15: 5-methoxy- 1-methyl-2, 4-dinitrobenzene; 16: Ethyl 3-(5-methoxy-2, 4-dinitrophenyl)-2-oxopropanoate; 17: Ethyl 6-amino- 5-methoxy-1H-indole-2-carboxylate; 18: 2-oxidanyl-2-oxoacetaldehyde; 19: 1-oxidanylpropane-1, 2-dione; 20: Ethyl 5-methoxy-7, 9-bis(oxidanylcarbonyl)-1H-pyrrolo[2, 3-f]quinoline-2-carboxylate; 21: 5-methoxy-1H- pyrrolo[2, 3-f]quinoline-2, 7, 9-tricarboxylic acid. |

第一类,含有吡啶环(环A)和吡咯环(环C)的底物通过收敛法形成芳香环(环B)合成PQQ (A+C→ABC)[42, 45]。Hendrickson等[42]以吡咯醛(1)和乌韦酮酸(2)为底物,通过Witting反应得到烯烃4的反式异构体;接着通过长时间的光引发的电环化反应异构为烯烃4,然后经过进一步环化、氧化、硝化和Zinin等反应生成化合物6;中间体6经过二氧化锰氧化、硝基化、加氢制胺以及重氮化等反应形成化合物7;最后在碱性条件下进行皂化形成PQQ。该合成方法步骤烦琐,且关键步骤光引发的电环化反应耗时很长,导致单批反应需要4周以上,效率低下。

第二类,含有吲哚环或类吲哚环(同时含有环B和环C)的底物通过收敛法添加环A合成PQQ (BC→ABC)[43, 46]。Glinkerman等[43]以化合物9为底物与1, 2, 3-三嗪(8)实现反电子需求的Diels-Alder反应进行环加成生成11;中间体11在氧化剂——二氯二氰基苯醌(dichloro dicyano benzoquinone, DDQ)的作用下氧化脱氢生成12,然后通过RuO2实现氧化反应生成邻醌13,最后对邻醌13的3个酯键进行皂化得到PQQ。该合成法首次利用非亲核性的全氟醇催化Diels-Alder反应对底物进行加环,仅需四步法即可合成PQQ,是目前已报道的PQQ化学合成法中产量最高的方法。该方法反应过程的多步反应需要氮气保护,生产过程需要真空设备,反应条件要求严苛。

第三类,含有芳香环(环B)的底物形成环A和环C两个杂环单位合成PQQ (B→ABC),该方法中环A或环C的合成顺序不固定[39, 44, 47]。程青芳等[44]通过5步法合成PQQ是该类方法的最便捷路径,以含有芳香环的5-甲基-2, 4-二硝基苯甲醚(15)为底物,在碱性条件下与草酸二乙酯(14)发生缩合反应形成16;16在还原剂作用下发生还原反应闭环得到17,然后在纯氧环境中与乙醛酸酯(18)和丙酮酸酯(19)通过Lewis酸催化生成20;最后发生酯水解反应和氧化反应得到PQQ。该方法需要使用水合肼和浓盐酸等具有强毒性或腐蚀性的试剂,且化合物20要在纯氧环境中合成,工艺设备及工况条件要求苛刻。

目前,化学合成PQQ的方法总收率均较低,第一类方法收产率仅有18%−20%,第三类方法的总收率在39%左右,只有第二类方法总收率能够达到56%。诸城市浩天药业有限公司生产PQQ采用的就是第二类化学合成法,以含有吲哚环的6-氨基-5-甲氧基-1吲哚-2-羧酸乙酯为底物,经过三步化学反应合成PQQ·Na2,其收率并未公布。化学合成法由于总收率低、反应条件苛刻、试剂昂贵且剧毒以及大量副产物产生等问题,导致生产成本高、固定资产投入大,极大地限制了化学法合成PQQ的工业化应用。截至2023年12月,向美国食品药品监督管理局(Food and Drug Administration, FDA)提交评价食品添加剂的安全性指标(generally recognized as safe, GRAS)文件进行PQQ·Na2注册的8家企业中,只有浩天药业采用的是化学合成法。

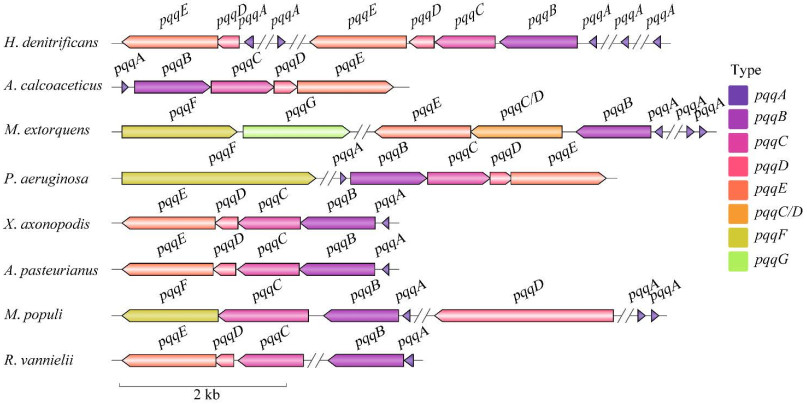

3 PQQ的生物合成 3.1 PQQ生物合成的过程PQQ属于核糖体合成和翻译后修饰肽(ribosomally synthesized and post-translationally modified peptides, RiPPs)。RiPPs是以核糖体翻译合成的线性多肽为前体,经过系列酶催化修饰形成的结构和功能多样化天然化合物[48]。研究人员通过基因组测序分析、基因敲除以及过表达确认只需4−7个基因参与PQQ的合成,分别命名为pqqA−G[49-50]。目前,PQQ的合成相关基因仅在细菌中发现;Shen等[51]对NCBI中的GenBank数据库进行分析,发现仅有126株菌的基因组含有PQQ合成相关基因,其中仅有6株为革兰氏阳性细菌;120株革兰氏阴性菌中,88%属于变形菌门(Proteobacteria),主要分布于α-、β-、γ-纲,少量分布于δ/ε-纲。PQQ合成相关基因在基因组上通常以基因簇的形式存在,并且基因排列顺序相对保守[52]。pqq基因簇中,pqqA−E为必需基因,pqqF编码的蛋白酶PqqF与pqqL、pqqH、pqqM或tldD等基因编码的蛋白酶是同工酶[53]。pqq基因簇在不同细菌中的组成有所不同(图 4),肺炎克雷伯菌(Klebsiella pneumoniae) NCTC418的pqq基因簇为pqqABCDEF单基因簇;扭脱甲基杆菌(Methylobacterium extorquens) AM1则包含pqqABCDE和pqqFG两个基因簇;脱氮生丝微菌(Hyphomicrobium denitrificns) FJNU-6含有pqqABCDE和pqqADE两个基因簇[54-56]。

|

| 图 4 不同菌株中参与PQQ合成的基因 Figure 4 Genes involved in PQQ synthesis in different strains. |

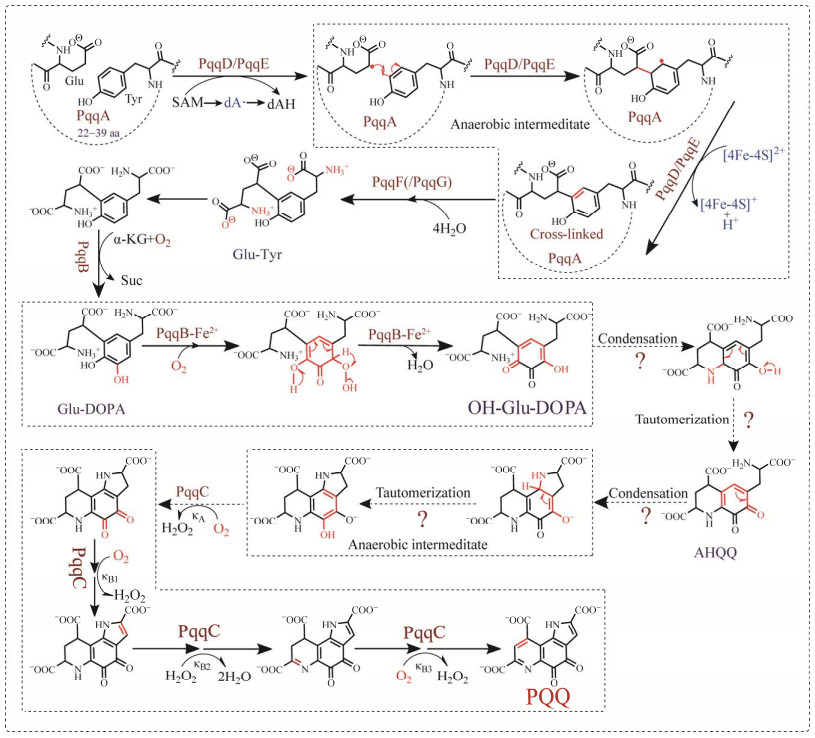

加州大学伯克利分校的Zhu等经过十几年的不懈努力下,终于在2020年将PQQ的生物合成途径基本阐释清楚[57]。PQQ合成的基本途径如图 5所示,主要分为5步。(1) 前体肽PqqA是一段含有22−39个氨基酸残基的小肽,由pqqA基因直接转录、翻译形成;PqqA中含有绝对保守序列Glu-X-X-X-Tyr,其中Glu残基和Tyr残基组成PQQ合成的骨架[51]。(2) PqqA首先被伴侣蛋白PqqD结合形成二元复合体,防止PqqA被降解并形成特定的空间结构与PqqE结合形成三元复合物;S-腺苷甲硫氨酸(S-adenosyl methionine, SAM)自由基酶PqqE催化PqqA中Glu的C9和Tyr的C9a缩合形成中间体cross-linked PqqA;缩合过程需要厌氧微环境来保证反应的进行,C9-C9a的连接需要[4Fe-4S]+作为电子受体,[4Fe-4S]+易被氧化成[4Fe-4S]2+,同时SAM断裂形成的脱氧腺苷自由基(deoxyadenosyl radical, dA)在有氧环境中极其不稳定[58]。(3) Cross-linked PqqA被蛋白酶PqqF (或PqqF/G二元复合物)特异性识别,并对Ser-Glu、Ser-Val、Ser-Tyr和Glu-Ser的丝氨酸位点进行剪切,释放出PQQ骨

|

| 图 5 PQQ的生物合成途径 Figure 5 Biosynthesis pathway of PQQ. |

架Glu-Ty[55]。(4) 骨架Glu-Tyr被金属β-内酰胺酶PqqB识别后进行2步羟基化形成OH-Glu-DOPA;反应过程需要两分子氧参与解耦羟基化插入酪氨酸环,第一步羟基化遵循经典的氢提取/羟基回弹机制(H-abstraction/ hydroxyl rebound mechanism),由FeⅣ-oxo辅助催化形成Glu-DOPA;第二步羟基化由Fe-O2辅助催化形成;接着,羟基化产物缩合异构为AHQQ,AHQQ在厌氧微环境中发生N1-C1a的缩合异构形成内酰胺中间体[59]。(5) 内酰胺中间体被无辅因子加氧酶PqqC在有氧条件下催化发生八电子参与的多步氧化反应,形成终产物PQQ;氧化反应过程中,步骤A、B1、B3共消耗3 mol O2,产生3 mol H2O2;步骤B2消耗其中的1 mol H2O2,产生2 mol H2O[60-61]。

3.2 PQQ生物合成的调控机制PQQ作为一种RiPPs,合成过程中的基因转录、翻译及产物修饰受到多种机制的调控[48]。Ramamoorthi等[62]首先在M. extorquens AM1中进行了PQQ合成调控机制的研究,发现pqqABCDE基因簇中pqqA和pqqB之间存在一个发夹结构;RNA印迹(Northern blotting)实验显示该基因簇编码2个不同的转录本,即高表达的前体肽PqqA转录本和低表达的PqqAB共同转录本;当分别以甲醇和琥珀酸为碳源进行培养时,发现PQQ的产量相差5倍以上,但两种条件下转录本的转录水平没有明显差别,推测PQQ的合成存在一种不依赖pqqA基因转录的调控机制;pqq基因簇启动子中存在AGAAACG序列,与甲醇脱氢酶启动子中的调控序列AGAAATG类似,同时敲除甲醇脱氢酶的双组分调控系统mxbD、mxbM和调控因子mxaB基因后发现敲除株的PQQ产量降低,推测这些调控蛋白可能会作用于pqq基因簇的启动子而调控PQQ合成。Ge等[63]发现在食甲基菌(Methylovorus sp.) MP688中PQQ的转录受到负反馈调控因子的调节;MP688的基因组上存在5个拷贝的pqqA基因,其中pqqA2的启动子区域含有抑制子(−300−−194 bp),敲除这段序列后PQQ产量提高了2−3倍。此外,pqq基因簇转录延伸存在着转录-翻译延伸耦合调控机制,Li等[64]基于普通生酮基古龙酸菌(Ketogulonicigenium vulgare) WSH-001内源I-C型CRISPR系统的Cas3基因,开发了CRISPRe促进转录延伸系统,靶向识别基因组中目的基因上的特殊原间隔序列邻近基序(protospacer adjacent motifs, PAMs)即iPAMs,促进DNA解链;K. vulgare WSH-001的pqqABCDEF基因簇上pqqA与pqqBCDEF之间的基因间序列(159 bp) G+C含量高达64.15%,解链受到限制;采用CRISPRe促进了基因间序列解链,pqqBCDEF基因转录水平从约1上升至约2 (34 h),PQQ产量最高上升50%。

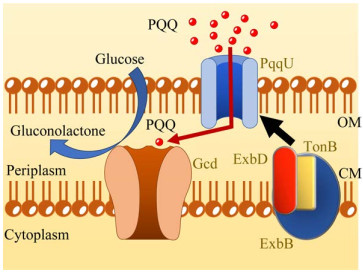

3.3 PQQ的胞内转运及胞外摄取系统PQQ在细胞质中合成,然后转运到细胞间质(细胞膜)与脱氢酶等受体结合发挥辅酶功能[65]。Ho等[66]在M. extorquens AM1中发现一种可以结合1当量未水合的PQQ周质(溶质)结合蛋白,并将该结合蛋白命名为PqqT,推测其可能参与PQQ的胞内运输。Wan等[67]对含有PqqB过表达质粒的氧化葡萄糖酸杆菌(Gluconobacter oxydans) WSH-003进行转录组分析,发现PQQ产量显著提高菌株的转运蛋白B932_1930或ABC转运渗透酶B932_2186的转录水平,提高了1.77倍或1.67倍,推测上述转运蛋白参与了PQQ的转运。PQQ通过Ca2+或Mg2+介导的配位键与脱氢酶相连,结合力较弱,主动运输到细胞间质后容易游离至胞外,柯崇榕[68]通过甲醇拮抗进行实验室定向驯化选育高产PQQ的H. denitrificans FJNU-R8时发现,当培养体系中甲醇浓度超过6%,胞内PQQ含量超过0.2 mg/g-DCW,胞外含量迅速降低,间接证实了PQQ是通过主动运输到达细胞间质。Hantke等[69]发现大肠杆菌(Escherichia coli)通过主动运输和协助扩散的方式摄取PQQ;低浓度(1 nmol/L) PQQ培养体系中,磷酸转移酶系统(phosphotransferase system, PTS)缺陷型E. coli K-12必须表达外膜蛋白TonB-ExbBD依赖转运体PqqU转运PQQ,保证菌株的快速生长(图 6);高浓度(≥33 nmol/L) PQQ培养体系中,亲水性的PQQ (330 Da)能够通过孔蛋白以扩散的方式穿过外膜进入胞内,保证菌株的生长[69]。

PQQ的生物合成目前仅在细菌中被发现,合成途径已经基本解释清楚,只需4−7个基因参与。PQQ在合成的转录起始、延伸等不同阶段受到多种机制的调控;合成后的PQQ以主动运输的方式到达细胞间质,并与脱氢酶以非共价键的形式结合;摄取过程中则同时具有主动运输和协助扩散两种方式。因此,深入研究PQQ的合成调控、胞内转运和胞外摄取机制,是提高PQQ产量的重要分子基础。

4 微生物发酵法生产PQQ及纯化工艺 4.1 PQQ生产工程菌的自源改造发酵法生产PQQ具有原料来源丰富、生产成本低、反应条件温和且工艺流程易控制等优点,成为了PQQ工业化生产的主要方式。PQQ工业化生产先驱Mitsubishi Gas公司及上市企业浙江海正药业股份有限公司和厦门金达威集团股份有限公司等7家企业生产PQQ均是采用以Hyphomicrobium为生产菌株的微生物发酵法。天然可大量产生PQQ的菌株主要来源于甲基杆菌属(Methylobacterium)、生丝微菌属(Hyphomicrobium)、副球菌属(Paracoccus)、葡萄糖杆菌属(Gluconobacter)和假单胞菌属(Pseudomonas)等[70]。其中,G. oxydans和K. pneumoniae因培养技术成熟且遗传操作体系较为完善,成为PQQ生物合成途径研究及代谢工程改造的常用菌株。叶润乐等[71]通过敲除丙酮酸脱羧酶基因GOX1081,减少乙酸的形成,并利用内源性组成型启动子P0169融合表达pqqABCDE基因簇及tldD基因,构建的重组菌G. oxydans T2培养48 h,PQQ产量提高了20.5倍(3 mg/L);Mi等[72]利用3个重复tac启动子融合表达pqqABCDEF基因簇,构建的重组菌K. pneumoniae (pET-3tac-pqq)培养24 h,PQQ产量提高了1.4倍(112 mg/L)。甲基营养菌是自然条件PQQ产量最高的细菌,通过代谢工程改造进一步提高产量是研究热点[73-76]。如表 1所示[77-86],Lu等[77]构建的含pqqABCDE基因簇和6个pqqA基因重组质粒的工程菌甲基球状菌(Methylopila sp.) YHT-1发酵7 d,PQQ产量提高了4.8倍(550 mg/L);寇航等[78]通过敲除hsp2基因优化四氢甲烷蝶呤(tetrahydromethanopterin, H4MPT)途径,构建的重组菌Methylovorus sp. J1-1 Δhsp2培养120 h,PQQ产量提高了1.1倍(812.64 mg/L)。然而,工业生产用的Hyphomicrobium遗传操作体系不成熟,代谢工程改造难度大。Gak等[79]在专利US201314010101公开,通过电转化技术将含有pqqABCDE基因簇及两个pqqA基因的质粒导入H. denitrificans ATCC 51888中,重组菌的PQQ产量从7.5 mg/L提高到10.6 mg/L。这是目前代谢工程改造H. denitrifican提高PQQ产量的唯一报道。本课题组柯崇榕[56]前期通过接合转移技术将含有pqqABCDE基因簇的宽宿主独立复制表达质粒pCM110成功导入H. denitrificns FJNU-6,抗性筛选获得阳性重组株,但重组菌PQQ产量没有变化;对多株阳性菌进行质粒抽提后测序,分析发现pCM110质粒不是独立存在于细胞质中,而是随机整合到基因组上;全基因组测序分析发现,不同于模式菌株ATCC 51888的Ⅱ型限制修饰系统,FJNU-6的限制性修饰系统为I型限制性修饰系统,这可能是pCM110质粒无法以环形结构存在于细胞质的原因。

| Receptor cell | Expression systems | Donor cell | Gene cluster | Experimental system | Product (mg/L) | Source |

| Methylotrophs | ||||||

| Methylopila sp. YHT-1 | Single plasmid system | Methylopila sp. YHT-1 | pqqABCDE, other 6 pqqA |

3 L | 550.00 | [77] |

| M. ethylovorus sp. J1-1 | Gene knockout | NA | Δhps2 | 5 L | 812.64 | [78] |

| M. extorquens AM1 | Single plasmid system | M. extorquens AM1 | pqqABCDE pqqA2A3 |

Test tube | 114.00 | [79] |

| H. denitrificns 51888 | Single plasmid system | H. denitrificns 51888 | pqqABCDE pqqA2A3 |

Test tube | 10.90 | [79] |

| M. extorquens AM1 | Gene mtation Single plasmid system |

M. extorquens AM1 | pqqABCDE | NA | 7.41 | [80] |

| Heterologous expression | ||||||

| E. coli BL21 | Single plasmid system | G. oxydans M5 | pqqABCDE | Shake flask | 2.00 | [81] |

| E. coli W3110 | CRISPR/Cas9 | G. oxydans 621H | pqqABCDE | Shake flask | 86.30 | [82] |

| E. coli BL21 | Dual plasmid system | K. pneumoniae | pqqABCDEF, phoE | Shake flask | 199.8 | [83] |

| E. coli K-12 | Single plasmid system | A. calcoaceticus | pqqABCDEF | NA | Very low | [84] |

| E. coli BL21 | Single plasmid system | K. pneumoniae DSM 2026 | pqqABCDEF | Shake flask | Unexpl- ained |

[85] |

| H. seropedicae Z67 | Single plasmid system | A. calcoaceticus | pqqI, II, III, IV, V, L, R | Test tube | 0.36 | [86] |

| H. seropedicae Z67 | Single plasmid system | P. fluorescens B161 | pqqABCDEFHIJKM | Test tube | 0.85 | [86] |

| NA means not expressed or not expressed in the original text. | ||||||

4.2 PQQ生产工程菌的异源构建

PQQ基因簇的异源表达是研究PQQ生物合成途径及其调控机制的方法之一。E. coli由于其自身完善的代谢途径研究和成熟的遗传操作体系,成为异源表达系统的首选宿主[87]。目前,PQQ基因簇的异源表达情况如表 1所示。Yang等[81]将来源于G. oxydans M5的pqqABCDE基因簇通过pTE28a质粒导入E. coli BL21,构建的工程菌在摇瓶水平培养60 h,PQQ产量达到2 mg/L。杨蒙雅等[82]将来源于G. oxydans 621H的pqqABCDE基因簇重组至E. coli PQQ-0基因组上,通过调节各基因的拷贝数优化表达比例、敲除铁-硫簇抑制基因iscR消除铁-硫簇抑制并过表达自源cdh基因和ompA基因强化PQQ的胞内需求和胞外转运,最后获得工程菌E. coli PQQ-17,在摇瓶水平培养72 h,PQQ产量达到86.3 mg/L。王朝绚[83]将来源于K. peneumoniae的pqqABCDEF基因簇和E. coli内源的gcd基因分别构建质粒后导入E. coli BL21,构建PQQ和葡萄糖耦合代谢途径,工程菌在10 mL体系过夜培养,PQQ产量达到87.52 mg/L,经培养基优化后摇瓶水平培养12 h,PQQ产量达到199.8 mg/L。这是目前异源表达PQQ产量最高的报道,但远无法达到工业化生产的要求。这可能与E. coli细胞内组成PQQ骨架的谷氨酸和酪氨酸的浓度相关,酪氨酸合成属于芳香族氨基酸生物合成途径的一部分,其途径中关键限速酶的酶活或表达强度受到代谢终产物的强烈反馈抑制或阻遏[70]。

4.3 PQQ高效生产菌株的选育PQQ的生物合成调控机制尚不清晰,且甲基营养菌的遗传操作体系不完善,通过代谢工程等手段大幅度提高菌株的PQQ产量存在较大的难度。因此,高产菌株的选育目前主要集中在从自然界中筛选产量较高的野生出发菌株并采用育种技术进行改造。张静等[88]以H. denitrificans CGMCC 1.12893作为出发菌株,通过常压室温等离子体(atmospheric and room temperature plasma, ARTP)诱变结合高通量筛选获得一株产量提高1.54倍的34号菌株,经培养基优化后在5 L发酵罐培养240 h,PQQ产量达到349.8 mg/L;Ren等[23]以H. denitrificns FJNU-6菌株作为出发菌株,通过适应性实验室定向进化(adaptive laboratory evolution, ALE)技术结合光谱法快速筛选体系选育获得一株产量提高2.35倍的高产突变株FJNU-A26,5 L发酵罐中利用两阶段pH调控策略培养144 h,PQQ产量达到1.52 g/L。微生物发酵的生产水平不仅取决于生产菌株本身的性能,而且与培养体系和培养条件息息相关。Urakami等[89]将Hyphomicrobium sp. strain TK0441培养体系中的Fe2+限制在1 mg/L,Mg2+维持在150 mg/L,30 L发酵罐中培养14 d,PQQ产量从167 mg/L增加至1 g/L;Liu等[90]通过两阶段供氧策略(55 h前60%溶氧、55 h后40%溶氧),协调菌体比生长速率和PQQ合成速率,H. denitrificns FJNU-6在5 L发酵罐中培养140 h,PQQ产量从0.73 g/L提高至1.07 g/L。Hyphomicrobium发酵产PQQ属于生长部分偶联型发酵,分批补料发酵稳定期短,单位细胞PQQ生产效率和甲醇转化率低。赵子刚等[91]采用半连续发酵工艺在20 L发酵罐中培养Hyphomicrobium sp. DSM 1869连续发酵18 d,PQQ生产效率为每天232.5 mg/L,甲醇平均转化率为8.21 g/L,比分批补料发酵分别提高49.8%和15%。

4.4 PQQ的纯化工艺PQQ的发酵液中含有大量的细菌菌体、剩余培养基成分、胞外蛋白和多糖等杂质,且PQQ含量不高还容易被蛋白质多肽等杂质螯合,形成不可逆的绿色复合物,造成PQQ含量的迅速降低。如何有效地分离是PQQ工业化生产急需解决的问题之一。目前开发的分离方法如表 2所示[92-107],马科等[92]利用季铵盐表面活性剂与烷烃和烷醇混合制备的超分子溶剂萃取发酵液中的PQQ,萃取液经氯化钠溶液反萃获得含PQQ的水相溶液,4 ℃静置24 h过滤即可获得纯度≥97.5%的PQQ红色晶体;杨雪鹏等[93]利用三辛胺和正己烷或者离子对试剂和碳酸氢钠缓冲液萃取氧化葡萄糖杆菌发酵液3−5次,含有PQQ的有机相上层经氨水反萃3−4次或阴离子、减压浓缩、冷冻干燥和纯水溶解,乙醇重结晶获得纯度≥99%的PQQ产品。然而,由于发酵液中PQQ浓度较低,萃取法需要使用大量的烷烃、烷醇等有机溶剂,提取成本高昂,操作环境要求严苛,工艺设备操作复杂。赵永芳等[100]开发了色谱法分离纯化发酵液中的PQQ。首先,利用亲水性DEAE-葡聚糖凝胶色谱法吸附发酵液中PQQ;接着,Tris-HCl洗脱、冷冻干燥、KCl饱和溶液溶解、低温结晶获得PQQ粗品;最后,粗品加水溶解后利用C18柱反向吸附、甲醇洗脱、冷冻干燥获得纯度≥98%的PQQ产品[100]。这一方法由于葡聚糖凝胶吸附性较差且成本高昂,仅适合于实验室规模从发酵液中小试制备PQQ。因此,Ke等[101]开发了操作简便、提取效率高、经济性好的大孔树脂吸附分离制备法。首先,采用微滤和超滤快速去除发酵液中的细胞碎片和多肽等大分子杂质,防止PQQ的螯合损失及引入新杂质;其次,利用纳滤浓缩预处理液,提高PQQ浓度并去除无机盐、有机酸等小分子,提高树脂吸附量,简化下游纯化工艺;最后,筛选XAD-1600非极性大孔树脂层析吸附酸化的PQQ溶液,磷酸盐缓冲液洗脱,低温结晶获得纯度大于99%,回收率82.6%的PQQ[101]。此外,葛欣等[108]通过基因敲除的手段对发酵菌株Methylovorus sp. MP688进行改造,去除了菌株合成胞外多糖的能力,减少了发酵液中多糖等代谢产物,从而简化了PQQ纯化工艺。

| Purification method | Pureness (%) | Recycling efficiency (%) | Source |

| Complexation extraction method | |||

| Supramolecular solvent complex extraction | > 97.50 | NA | [92] |

| Complex extraction | 99.00 | NA | [93] |

| Membrane filtration combination solvent extraction | > 99.30 | > 69.00 | [94] |

| Membrane filtration, alting out, magnetic microspheres | > 99.60 | 78.30 | [95] |

| Magnetic nanospheres prepared by reverse micelle method | ≥97.00 | ≥95.60 | [96] |

| Molecular imprinting solid hase extraction (MISPE) | > 99.00 | > 90.00 | [97] |

| Adsorbent combination membrane filtration | ≥98.00 | ≥85.00 | [98] |

| Ion pair aqueous two-phase extraction | 99.00 | ≥85.20 | [99] |

| Chromatography | |||

| DEAE-sephadex with seppak C18 column | ≥98.00 | NA | [100] |

| Membrane filtration combination non polar macroporous resin | 99.00 | 82.60 | [101] |

| Non polar macroporous resin combination polyamide column | 99.00 | NA | [102] |

| Weak-base anion-exchange resin | 98.00 | NA | [103] |

| Sephadex chromatography combination HSCCC | 93.70 | 53.00 | [104] |

| Flocculant combination mixed macroporous resin | 99.60 | 72.00 | [105] |

| Polyamide resin combination membrane filtration | ≥98.00 | 90.00 | [106] |

| Non polar macroporous resin combination hydrophilic C18 silica filler | > 99.50 | NA | [107] |

| NA means not expressed in the original text. | |||

甲基营养菌是天然生产PQQ最多的微生物,但调控机制不清晰,遗传操作工具不成熟导致通过代谢工程改造提升PQQ产量的效果不理想。E. coli具有完善的代谢途径研究和成熟的遗传操作体系,是理想的异源表达底盘菌,但目前构建的工程菌PQQ产量最高仅为199.8 mg/L[83]。单纯过表达pqq基因簇或相关基因不能有效提升PQQ产量,这可能与复杂的PQQ合成调控和转运机制有关。非理性设计选育高产突变株并进行培养工艺的优化是目前提高甲基营养菌PQQ产量的主要方式,最高产量已达到2.35 g/L[109]。PQQ需要通过纯化结晶才能得到纯品,树脂层析法成本低廉、回收纯度高且体系易放大,是PQQ工业化生产的主要方式,但是处理使用后的树脂会产生大量污水,无害化处理较为复杂。

5 总结PQQ广泛分布在细菌、真菌和动植物体内,在多种疾病的研究中表现出了巨大的预防和治疗潜力,同时对经济动植物具有保护和增产作用,应用前景广阔。化学法生产PQQ存在总收率低、反应条件苛刻和副产物等较多痛点,逐渐被生物合成法取代。目前,利用生物合成法工业化生产PQQ的策略是,通过野生菌诱变育种获得PQQ的高产突变株,结合不同调控策略获得高PQQ浓度的发酵液;利用安全性高、吸附能力强、可重复使用的树脂作为层析材料对PQQ发酵液进行分离操作,降低纯化过程中填充剂成本和有机溶剂的使用量;获得的洗脱液经低温结晶得到纯度99%的PQQ产品。PQQ的生物合成具有原材料丰富、反应条件温和且工艺流程易操作的优势,并且其生物合成途径已基本阐明,但由于调控机制不清晰、遗传操作体系不完善,导致PQQ重组工程菌产量低而难以实现工业化生产。相信将来可以通过解析PQQ生物合成过程中的调控和转运机制、利用合成生物学技术构建成熟的遗传操作系统,并结合发酵条件和分离纯化工艺优化等多种策略解决大规模生产中存在的问题,进一步提高PQQ产量,从而创造更好的经济效益。

| [1] | HAUGE JG. Glucose dehydrogenase of Bacterium anitratum: an enzyme with a novel prosthetic group[J]. The Journal of Biological Chemistry, 1964, 239(11): 3630-3639 DOI:10.1016/S0021-9258(18)91183-X. |

| [2] | SALISBURY SA, FORREST HS, CRUSE WBT, KENNARD O. A novel coenzyme from bacterial primary alcohol dehydrogenases[J]. Nature, 1979, 280: 843-844 DOI:10.1038/280843a0. |

| [3] |

牟京霞, 刘建民. 吡咯喹啉醌的生理功能及研究进展[J]. 当代化工研究, 2020(10): 137-138.

DOI:10.3969/j.issn.1672-8114.2020.10.067 MOU JX, LIU JM. Physiological function and research progress of pyrroloquinoline quinone[J]. Modern Chemical Research, 2020(10): 137-138 (in Chinese). |

| [4] | KRÜSEMANN JL, RAINALDI V, COTTON CA, CLAASSENS NJ, LINDNER SN. The cofactor challenge in synthetic methylotrophy: bioengineering and industrial applications[J]. Current Opinion in Biotechnology, 2023, 82: 102953 DOI:10.1016/j.copbio.2023.102953. |

| [5] | CHAN SI, CHUANKHAYAN P, REDDY NAREDDY PK, TSAI IK, TSAI YF, CHEN KHC, YU SSF, CHEN CJ. Mechanism of pyrroloquinoline quinone-dependent hydride transfer chemistry from spectroscopic and high-resolution X-ray structural studies of the methanol dehydrogenase from Methylococcus capsulatus (bath)[J]. Journal of the American Chemical Society, 2021, 143(9): 3359-3372 DOI:10.1021/jacs.0c11414. |

| [6] | STINES-CHAUMEIL C, MAVRÉ F, KAUFFMANN B, MANO N, LIMOGES B. Mechanism of reconstitution/activation of the soluble PQQ-dependent glucose dehydrogenase from Acinetobacter calcoaceticus: a comprehensive study[J]. ACS Omega, 2020, 5(4): 2015-2026 DOI:10.1021/acsomega.9b04034. |

| [7] | MATSUMURA H, UMEZAWA K, TAKEDA K, SUGIMOTO N, ISHIDA T, SAMEJIMA M, OHNO H, YOSHIDA M, IGARASHI K, NAKAMURA N. Discovery of a eukaryotic pyrroloquinoline quinone-dependent oxidoreductase belonging to a new auxiliary activity family in the database of carbohydrate-active enzymes[J]. PLoS One, 2014, 9(8): e104851 DOI:10.1371/journal.pone.0104851. |

| [8] | MATSUSHITA K, TOYAMA H, YAMADA M, ADACHI O. Quinoproteins: structure, function, and biotechnological applications[J]. Applied Microbiology and Biotechnology, 2002, 58(1): 13-22 DOI:10.1007/s00253-001-0851-1. |

| [9] |

杨璐, 熊向华, 汪建华, 张惟材. 吡咯喹啉醌研究进展[J]. 生物技术通讯, 2009, 20(6): 874-879.

YANG L, XIONG XH, WANG JH, ZHANG WC. Advances on the research of pyrroloquinoline quinone[J]. Letters in Biotechnology, 2009, 20(6): 874-879 (in Chinese). |

| [10] | TAKEDA K, UMEZAWA K, VÁRNAI A, EIJSINK VG, IGARASHI K, YOSHIDA M, NAKAMURA N. Fungal PQQ-dependent dehydrogenases and their potential in biocatalysis[J]. Current Opinion in Chemical Biology, 2019, 49: 113-121 DOI:10.1016/j.cbpa.2018.12.001. |

| [11] | IKEMOTO K, MORI S, MUKAI KZ. Synthesis and crystal structure of pyrroloquinoline quinol (PQQH2) and pyrroloquinoline quinone (PQQ)[J]. Acta Crystallographica Section B, Structural Science, Crystal Engineering and Materials, 2017, 73(Pt 3): 489-497. |

| [12] | DANAF NA, KRETZSCHMAR J, JAHN B, SINGER H, POL A, OP den CAMP HJM, STEUDTNER R, LAMB DC, DROBOT B, DAUMANN LJ. Studies of pyrroloquinoline quinone species in solution and in lanthanide-dependent methanol dehydrogenases[J]. Physical Chemistry Chemical Physics: PCCP, 2022, 24(25): 15397-15405 DOI:10.1039/D2CP00311B. |

| [13] | WHITAKER WB, SANDOVAL NR, BENNETT RK, FAST AG, PAPOUTSAKIS ET. Synthetic methylotrophy: engineering the production of biofuels and chemicals based on the biology of aerobic methanol utilization[J]. Current Opinion in Biotechnology, 2015, 33: 165-175 DOI:10.1016/j.copbio.2015.01.007. |

| [14] | STITES TE, MITCHELL AE, RUCKER RB. Physiological importance of quinoenzymes and the O-quinone family of cofactors[J]. The Journal of Nutrition, 2000, 130(4): 719-727 DOI:10.1093/jn/130.4.719. |

| [15] | XIANG X, KWAME AW, QING YL, LI S, WANG M, REN JY. Natural antioxidants inhibit oxidative stress-induced changes in the morphology and motility of cells[J]. Food Bioscience, 2023, 52: 102442 DOI:10.1016/j.fbio.2023.102442. |

| [16] | GAO Y, KAMOGASHIRA T, FUJIMOTO C, IWASAKI S, YAMASOBA T. Pyrroloquinoline quinone (PQQ) protects mitochondrial function of HEI-OC1 cells under premature senescence[J]. NPJ Aging, 2022, 8: 3 DOI:10.1038/s41514-022-00083-0. |

| [17] | SHAFIQ M, LONE ZR, BHARATI P, MAHAPATRA S, RAI P, KHANDELWAL N, GAIKWAD AN, JAGAVELU K, HANIF K. Pyrroloquinoline quinone (PQQ) improves pulmonary hypertension by regulating mitochondrial and metabolic functions[J]. Pulmonary Pharmacology & Therapeutics, 2022, 76: 102156. |

| [18] | BORETTI A. PQQ supplementation and SARS-CoV-2 spike protein-induced heart inflammation[J]. Natural Product Communications, 2022, 17(3): 1934578X221080929. |

| [19] | KATO C, KAWAI E, SHIMIZU N, MIKEKADO T, KIMURA F, MIYAZAWA T, NAKAGAWA K. Determination of pyrroloquinoline quinone by enzymatic and LC-MS/MS methods to clarify its levels in foods[J]. PLoS One, 2018, 13(12): e0209700 DOI:10.1371/journal.pone.0209700. |

| [20] | MITCHELL AE, JONES AD, MERCER RS, RUCKER RB. Characterization of pyrroloquinoline quinone amino acid derivatives by electrospray ionization mass spectrometry and detection in human milk[J]. Analytical Biochemistry, 1999, 269(2): 317-325 DOI:10.1006/abio.1999.4039. |

| [21] | KASAHARA T, KATO T. A new redox-cofactor vitamin for mammals[J]. Nature, 2003, 422(6934): 832 DOI:10.1038/422832a. |

| [22] | AMES BN. Prolonging healthy aging: longevity vitamins and proteins[J]. Proceedings of the National Academy of Sciences of the United States of America, 2018, 115(43): 10836-10844. |

| [23] | REN Y, YANG XW, DING LT, LIU DF, TAO Y, HUANG JZ, KE CR. Adaptive evolutionary strategy coupled with an optimized biosynthesis process for the efficient production of pyrroloquinoline quinone from methanol[J]. Biotechnology for Biofuels and Bioproducts, 2023, 16(1): 11 DOI:10.1186/s13068-023-02261-y. |

| [24] | PENG Y, XU D, DING YD, ZHOU XQ. Supplementation of PQQ from pregnancy prevents MK-801-induced schizophrenia-like behaviors in mice[J]. Psychopharmacology, 2022, 239(7): 2263-2275 DOI:10.1007/s00213-022-06113-9. |

| [25] | YAMADA Y, NISHII K, KUWATA K, NAKAMICHI M, NAKANISHI K, SUGIMOTO A, IKEMOTO K. Effects of pyrroloquinoline quinone and imidazole pyrroloquinoline on biological activities and neural functions[J]. Heliyon, 2020, 6(1): e03240 DOI:10.1016/j.heliyon.2020.e03240. |

| [26] | TAMAKOSHI M, SUZUKI T, NISHIHARA E, NAKAMURA S, IKEMOTO K. Pyrroloquinoline quinone disodium salt improves brain function in both younger and older adults[J]. Food & Function, 2023, 14(5): 2496-2501. |

| [27] | WU YH, ZHAO ML, LIN ZH. Pyrroloquinoline quinone (PQQ) alleviated sepsis-induced acute liver injury, inflammation, oxidative stress and cell apoptosis by downregulating CUL3 expression[J]. Bioengineered, 2021, 12(1): 2459-2468 DOI:10.1080/21655979.2021.1935136. |

| [28] | HARRIS CB, CHOWANADISAI W, MISHCHUK DO, SATRE MA, SLUPSKY CM, RUCKER RB. Dietary pyrroloquinoline quinone (PQQ) alters indicators of inflammation and mitochondrial-related metabolism in human subjects[J]. The Journal of Nutritional Biochemistry, 2013, 24(12): 2076-2084 DOI:10.1016/j.jnutbio.2013.07.008. |

| [29] | NAKANO M, KAWASAKI Y, SUZUKI N, TAKARA T. Effects of pyrroloquinoline quinone disodium salt intake on the serum cholesterol levels of healthy Japanese adults[J]. Journal of Nutritional Science and Vitaminology, 2015, 61(3): 233-240 DOI:10.3177/jnsv.61.233. |

| [30] | WEN LC, LU XY, WANG R, JIN XW, HU LQ, YOU CW. Pyrroloquinoline quinone induces chondrosarcoma cell apoptosis by increasing intracellular reactive oxygen species[J]. Molecular Medicine Reports, 2018, 17(5): 7184-7190. |

| [31] | ZHANG BR, WANG CX, YANG W, ZHANG HY, MENG QW, SHI BM, SHAN AS. Transcriptome analysis of the effect of pyrroloquinoline quinone disodium (PQQ·Na2) on reproductive performance in sows during gestation and lactation[J]. Journal of Animal Science and Biotechnology, 2019, 10(1): 62 DOI:10.1186/s40104-019-0369-y. |

| [32] | WANG J, ZHANG HJ, SAMUEL KG, LONG C, WU SG, YUE HY, SUN LL, QI GH. Effects of dietary pyrroloquinoline quinone disodium on growth, carcass characteristics, redox status, and mitochondria metabolism in broilers[J]. Poultry Science, 2015, 94(2): 215-225 DOI:10.3382/ps/peu050. |

| [33] | LIU GQ, SUN GM, LIAO XD, HUANG JZ, GUO MJ, ZHANG LY, GUO YL, LU L, LUO XG. Effect of dietary supplementation of pyrroloquinoline quinone disodium on growth performance, meat quality and antioxidative ability of broilers[J]. Journal of Integrative Agriculture, 2020, 19(7): 1850-1856 DOI:10.1016/S2095-3119(19)62851-0. |

| [34] | SHI QC, WEN ZY, WANG J, HU P, ZOU YC, WANG SQ, QIN CJ. Effects of dietary pyrroloquinoline quinone on growth performance, serum biochemical parameters, antioxidant status, and growth-related genes expressions in juvenile yellow catfish, Pelteobagrus fulvidraco[J]. Frontiers in Marine Science, 2022, 9: 989948 DOI:10.3389/fmars.2022.989948. |

| [35] |

李震, 罗杰, 张清壮, 许石剑, 罗富方, 刘胜传, 宋莉丹, 李鑫. 吡咯喹啉醌对植烟土壤和烤烟生长的影响[J]. 湖南农业科学, 2020(9): 14-18.

LI Z, LUO J, ZHANG QZ, XU SJ, LUO FF, LIU SC, SONG LD, LI X. Effects of pyrroloquinoline quinone on tobacco growing soil and tobacco growth[J]. Hunan Agricultural Sciences, 2020(9): 14-18 (in Chinese). |

| [36] |

朱云集, 王永华, 郭天财, 刘卫群, 赵永芳. 吡咯喹啉醌对冬小麦某些生理特性和穗部性状的影响(简报)[J]. 植物生理学通讯, 2000, 36(4): 330-332.

ZHU YJ, WANG YH, GUO TC, LIU WQ, ZHAO YF. Effects of pyrroloquinoline quinone on some physiological characteristics and panicle characters of winter wheat (brief report)[J]. Plant Physiology Communications, 2000, 36(4): 330-332 (in Chinese). |

| [37] | LI SF, TANG T, MA GL, LIU DC, PENG YJ, ZHANG YZ. Pyrroloquinoline quinone treatment induces rice resistance to sheath blight through jasmonic acid pathway[J]. Agronomy, 2022, 12(11): 2660 DOI:10.3390/agronomy12112660. |

| [38] |

何曙光, 李华平, 戴力, 刘洋, 匡炜, 方宝华, 赵杨. PQQ对低温胁迫下早稻幼苗生理特性的影响[J]. 湖南农业科学, 2020(5): 17-20.

HE SG, LI HP, DAI L, LIU Y, KUANG W, FANG BH, ZHAO Y. Effects of PQQ on physiological characteristics of early rice seedlings under low temperature stress[J]. Hunan Agricultural Sciences, 2020(5): 17-20 (in Chinese). |

| [39] | GAINOR JA, WEINREB SM. Total synthesis of methoxatin, the coenzyme of methanol dehydrogenase and glucose dehydrogenase[J]. Journal of Organic Chemistry, 1981, 46(21): 4317-4319 DOI:10.1021/jo00334a053. |

| [40] | COREY EJ, TRAMONTANO A. Total synthesis of the quinonoid alcohol dehydrogenase coenzyme (1) of methylotrophic bacteria[J]. Journal of the American Chemical Society, 1981, 103(18): 5599-5600 DOI:10.1021/ja00408a067. |

| [41] | SCHRÖDER B, GAICH T. Methoxatin as a target in total synthesis[J]. Synthesis, 2017, 49(8): 1746-1756 DOI:10.1055/s-0036-1589492. |

| [42] | ENDRICKSON JB, de VRIES JG. A convergent total synthesis of methoxatin[J]. The Journal of Organic Chemistry, 1982, 47(6): 1148-1150 DOI:10.1021/jo00345a057. |

| [43] | GLINKERMAN CM, BOGER DL. Catalysis of heterocyclic azadiene cycloaddition reactions by solvent hydrogen bonding: concise total synthesis of methoxatin[J]. Journal of the American Chemical Society, 2016, 138(38): 12408-12413 DOI:10.1021/jacs.6b05438. |

| [44] |

CHENG QF, XU DQ, WANG YW, QIU H, WANG QF. Preparation method of PQQ: CN114890999B[P]. 2023-10-24 (in Chinese). 程青芳, 徐东强, 王伊文, 仇浩, 王启发. 一种PQQ的制备方法: CN114890999B[P]. 2023-10-24. |

| [45] | HENDRICKSON JB, de VRIES JG. Total synthesis of the novel coenyzme methoxatin[J]. The Journal of Organic Chemistry, 1985, 50(10): 1688-1695 DOI:10.1021/jo00210a024. |

| [46] | BUCHI G, BOTKIN JH, LEE GCM, YAKUSHIJIN K. A synthesis of methoxatin[J]. Journal of the American Chemical Society, 1985, 107(19): 5555-5556 DOI:10.1021/ja00305a055. |

| [47] | PUTHIAPARAMPIL TT, SAMBASIVAM G, GOVINDA RG, KORAMANGALA RC. Compounds of 3-(5-substituted oxy-2, 4-dinitrophenyl)-2-oxo-propionic acid ester, synthesis and applications thereof: US201414218244[P]. 2015.08. 25. |

| [48] | RUBIN GM, DING YS. Recent advances in the biosynthesis of RiPPs from multicore-containing precursor peptides[J]. Journal of Industrial Microbiology & Biotechnology, 2020, 47(9): 659-674. |

| [49] | VELTEROP JS, SELLINK E, MEULENBERG JJ, DAVID S, BULDER I, POSTMA PW. Synthesis of pyrroloquinoline quinone in vivo and in vitro and detection of an intermediate in the biosynthetic pathway[J]. Journal of Bacteriology, 1995, 177(17): 5088-5098 DOI:10.1128/jb.177.17.5088-5098.1995. |

| [50] | GOOSEN N, HORSMAN HPA, HUINEN RGM, de GROOT A, van de PUTTE P. Genes involved in the biosynthesis of PQQ from Acinetobacter calcoaceticus[J]. Antonie Van Leeuwenhoek, 1989, 56(1): 85-91 DOI:10.1007/BF00822588. |

| [51] | SHEN YQ, BONNOT F, IMSAND EM, RoseFIGURA JM, SJÖLANDER K, KLINMAN JP. Distribution and properties of the genes encoding the biosynthesis of the bacterial cofactor, pyrroloquinoline quinone[J]. Biochemistry, 2012, 51(11): 2265-2275 DOI:10.1021/bi201763d. |

| [52] | OMELCHENKO MV, MAKAROVA KS, WOLF YI, ROGOZIN IB, KOONIN EV. Evolution of mosaic operons by horizontal gene transfer and gene displacement in situ[J]. Genome Biology, 2003, 4(9): R55 DOI:10.1186/gb-2003-4-9-r55. |

| [53] | LO SC, TSAI SY, CHANG WH, WU IC, SOU NL, HUNG SH W, CHIANG EP I, HUANG CC. Characterization of the pyrroloquinoline quinone producing Rhodopseudomonas palustris as a plant growth-promoting bacterium under photoautotrophic and photoheterotrophic culture conditions[J]. International Journal of Molecular Sciences, 2023, 24(18): 14080 DOI:10.3390/ijms241814080. |

| [54] | MEULENBERG JJM, SELLINK E, RIEGMAN NH, POSTMA PW. Nucleotide sequence and structure of the Klebsiella pneumoniae pqq operon[J]. Molecular and General Genetics MGG, 1992, 232(2): 284-295 DOI:10.1007/BF00280008. |

| [55] | MARTINS AM, LATHAM JA, MARTEL PJ, BARR I, IAVARONE AT, KLINMAN JP. A two-component protease in Methylorubrum extorquens with high activity toward the peptide precursor of the redox cofactor pyrroloquinoline quinone[J]. Journal of Biological Chemistry, 2019, 294(41): 15025-15036 DOI:10.1074/jbc.RA119.009684. |

| [56] |

KE CR. Breedning, preparation and biosyntheic pathway analysis of pyrroloquinoline quinone[D]. Fuzhou: Doctoral Dissertation of Fujian Normal University, 2016 (in Chinese). 柯崇榕. 吡咯喹啉醌的高产菌株选育、发酵制备及生物合成途径的研究[D]. 福州: 福建师范大学博士学位论文, 2016. |

| [57] | ZHU W, KLINMAN JP. Biogenesis of the peptide-derived redox cofactor pyrroloquinoline quinone[J]. Current Opinion in Chemical Biology, 2020, 59: 93-103 DOI:10.1016/j.cbpa.2020.05.001. |

| [58] | LATHAM JA, IAVARONE AT, BARR I, JUTHANI PV, KLINMAN JP. PqqD is a novel peptide chaperone that forms a ternary complex with the radical S-adenosylmethionine protein PqqE in the pyrroloquinoline quinone biosynthetic pathway[J]. Journal of Biological Chemistry, 2015, 290(20): 12908-12918 DOI:10.1074/jbc.M115.646521. |

| [59] | LIU YR, LIU YJ. Computational study of aromatic hydroxylation catalyzed by the iron-dependent hydroxylase PqqB involved in the biosynthesis of redox cofactor pyrroloquinoline quinone[J]. Inorganic Chemistry, 2022, 61(15): 5943-5956 DOI:10.1021/acs.inorgchem.2c00419. |

| [60] | ZHU W, MARTINS AM, KLINMAN JP. Methods for expression, purification, and characterization of PqqE, a radical SAM enzyme in the PQQ biosynthetic pathway[J]. Methods in Enzymology, 2018, 606: 389-420. |

| [61] | MAGNUSSON OT, RoseFIGURA JM, TOYAMA H, SCHWARZENBACHER R, KLINMAN JP. Pyrroloquinoline quinone biogenesis: characterization of PqqC and its H84N and H84A active site variants[J]. Biochemistry, 2007, 46(24): 7174-7186 DOI:10.1021/bi700162n. |

| [62] | RAMAMOORTHI R, LIDSTROM ME. Transcriptional analysis of pqqD and study of the regulation of pyrroloquinoline quinone biosynthesis in Methylobacterium extorquens AM1[J]. Journal of Bacteriology, 1995, 177(1): 206-211 DOI:10.1128/jb.177.1.206-211.1995. |

| [63] | GE X, WANG WX, DU BH, WANG JH, XIONG XH, ZHANG WC. Multiple pqqA genes respond differently to environment and one contributes dominantly to pyrroloquinoline quinone synthesis[J]. Journal of Basic Microbiology, 2015, 55(3): 312-323 DOI:10.1002/jobm.201300037. |

| [64] | LI D, CHEN YH, HUANG F, WANG JM, LI XF, YANG Y. CRISPRe: an innate transcriptional enhancer for endogenous genes in CRISPR-Cas immunity[J]. iScience, 2023, 26(10): 107814 DOI:10.1016/j.isci.2023.107814. |

| [65] | PUEHRINGER S, METLITZKY M, SCHWARZENBACHER R. The pyrroloquinoline quinone biosynthesis pathway revisited: a structural approach[J]. BMC Biochemistry, 2008, 9(1): 8 DOI:10.1186/1471-2091-9-8. |

| [66] | HO JV, COTRUVO JA. A periplasmic binding protein for pyrroloquinoline quinone[J]. Biochemistry, 2019, 58(23): 2665-2669 DOI:10.1021/acs.biochem.9b00358. |

| [67] | WAN H, XIA Y, LI JH, KANG Z, ZHOU JW. Identification of transporter proteins for PQQ-secretion pathways by transcriptomics and proteomics analysis in Gluconobacter oxydans WSH-003[J]. Frontiers of Chemical Science and Engineering, 2017, 11(1): 72-88 DOI:10.1007/s11705-016-1580-4. |

| [68] |

柯崇榕. 适应性驯化选育高产吡咯喹啉醌的生丝微菌突变株[J]. 生物工程学报, 2020, 36(1): 152-161.

KE CR. Breeding of Hyphomicrobium denitrificans for high production of pyrroloquinoline quinone by adaptive directed domestication[J]. Chinese Journal of Biotechnology, 2020, 36(1): 152-161 (in Chinese). |

| [69] | HANTKE K, FRIZ S. The TonB-dependent uptake of pyrroloquinoline-quinone (PQQ) and secretion of gluconate by Escherichia coli K-12[J]. Molecular Microbiology, 2022, 118(4): 417-425 DOI:10.1111/mmi.14975. |

| [70] |

王光路, 王梦园, 周忆菲, 马科, 张帆, 杨雪鹏. 吡咯喹啉醌生物合成研究进展[J]. 中国生物工程杂志, 2021, 41(1): 103-113.

WANG GL, WANG MY, ZHOU YF, MA K, ZHANG F, YANG XP. Research progress in pyrrologuinoline quinone biosynthesis[J]. China Biotechnology, 2021, 41(1): 103-113 (in Chinese). |

| [71] |

叶润乐, 李沣, 丁凡, 赵振辉, 陈晟, 袁建锋. 基于重组氧化葡萄糖酸杆菌生物合成吡咯喹啉醌[J]. 生物工程学报, 2020, 36(6): 1138-1149.

YE RL, LI F, DING F, ZHAO ZH, CHEN S, YUAN JF. Synthesis of pyrroloquinoline quinone by recombinant Gluconobacter oxydans[J]. Chinese Journal of Biotechnology, 2020, 36(6): 1138-1149 (in Chinese). |

| [72] | MI ZW, CHENG JC, ZHAO P, TIAN PF, TAN TW. Improved production of pyrroloquinoline quinone by simultaneous augmentation of its synthesis gene expression and glucose metabolism in Klebsiella pneumoniae[J]. Current Microbiology, 2020, 77(7): 1174-1183 DOI:10.1007/s00284-020-01918-3. |

| [73] | TOYAMA H, CHISTOSERDOVA L, LIDSTROM ME. Sequence analysis of pqq genes required for biosynthesis of pyrroloquinoline quinone in Methylobacterium extorquens AM1 and the purification of a biosynthetic intermediate[J]. Microbiology, 1997, 143(Pt 2): 595-602. |

| [74] | van KLEEF MA, DUINE JA. Factors relevant in bacterial pyrroloquinoline quinone production[J]. Applied and Environmental Microbiology, 1989, 55(5): 1209-1213 DOI:10.1128/aem.55.5.1209-1213.1989. |

| [75] | AMEYAMA M, HAYASHI M, MATSUSHITA K, SHINAGAWA E, ADACHI O. Microbial production of pyrroloquinoline quinone[J]. Agricultural and Biological Chemistry, 2014, 48(2): 561-565. |

| [76] | MCINTIRE WS, WEYLER W. Factors affecting the production of pyrroloquinoline quinone by the Methylotrophic bacterium W3A1[J]. Applied and Environmental Microbiology, 1987, 53(9): 2183-2188 DOI:10.1128/aem.53.9.2183-2188.1987. |

| [77] | LU WL, WU YS, NUNN D, YU O. Methods for improving pyrroloquinoline quinone production in Methylopila: US2022078752[P]. 2023.05. 04. |

| [78] |

寇航, 王艳梅, 李彤, 薄明井, 张惟材, 熊向华, 黎明. 基于Methylovorus sp. J1-1基因组尺度代谢网络优化吡咯喹啉醌合成[J]. 生物技术通报, 2022, 38(2): 173-183.

KOU H, WANG YM, LI T, BO MJ, ZHANG WC, XIONG XH, LI M. Fermentation optimization for PQQ synthesis based on the genome-scale metabolic model of Methylovorus sp. J1-1[J]. Biotechnology Bulletin, 2022, 38(2): 173-183 (in Chinese). |

| [79] | GAK RE, GORSHKOVA NV, TOKMAKOVA IL. Method for producing pyrroloquinoline quinone using a bacterium of the genus Methylobacterium or Hyphomicrobium: US201314010101[P]. 2012.09. 07. |

| [80] |

吴波, 赵永芳, 王银善. 吡咯喹啉醌(PQQ)合成基因对PQQ产量的影响[J]. 武汉大学学报(自然科学版), 1999(6): 869-872.

WU B, ZHAO YF, WANG YS. The effect on production of PQQ directed by the pyrroloquinoline quinone biosynthesis genes' copy number[J]. Wuhan University Journal of Natural Sciences, 1999(6): 869-872 (in Chinese). |

| [81] | YANG XP, ZHONG GF, LIN JP, MAO DB, WEI DZ. Pyrroloquinoline quinone biosynthesis in Escherichia coli through expression of the Gluconobacter oxydans pqqABCDE gene cluster[J]. Journal of Industrial Microbiology and Biotechnology, 2010, 37(6): 575-580 DOI:10.1007/s10295-010-0703-z. |

| [82] |

杨蒙雅, 张春月, 伊进行, 王怡明, 卓明洋, 马倩, 谢希贤. 大肠杆菌中吡咯喹啉醌合成途径的构建[J]. 食品与生物技术学报, 2022, 41(8): 75-85.

YANG MY, ZHANG CY, YI JH, WANG YM, ZHUO MY, MA Q, XIE XX. Construction of pyrroloquinoline quinone synthesis pathway in Escherichia coli[J]. Journal of Food Science and Biotechnology, 2022, 41(8): 75-85 (in Chinese). |

| [83] |

WANG ZX. Engineering strains for production of pyrroloquinoline quinone and dissecting key genes[D]. Beijing: Master's Thesis of Beijing University of Chemical Technology, 2013 (in Chinese). 王朝绚. 吡咯喹啉醌工程菌构建及关键基因研究[D]. 北京: 北京化工大学硕士学位论文, 2013. |

| [84] | GOOSEN N, HORSMAN HP, HUINEN RG, van de PUTTE P. Acinetobacter calcoaceticus genes involved in biosynthesis of the coenzyme pyrrolo-quinoline-quinone: nucleotide sequence and expression in Escherichia coli K-12[J]. Journal of Bacteriology, 1989, 171(1): 447-455 DOI:10.1128/jb.171.1.447-455.1989. |

| [85] | SUN JG, HAN ZY, GE XZ, TIAN PF. Distinct promoters affect pyrroloquinoline quinone production in recombinant Escherichia coli and Klebsiella pneumoniae[J]. Current Microbiology, 2014, 69(4): 451-456 DOI:10.1007/s00284-014-0607-7. |

| [86] | WAGH J, SHAH S, BHANDARI P, ARCHANA G, KUMAR GN. Heterologous expression of pyrroloquinoline quinone (pqq) gene cluster confers mineral phosphate solubilization ability to Herbaspirillum seropedicae Z67[J]. Applied Microbiology and Biotechnology, 2014, 98(11): 5117-5129 DOI:10.1007/s00253-014-5610-1. |

| [87] | MATSUSHITA K, ARENTS JC, BADER R, YAMADA M, ADACHI O, POSTMA PW. Escherichia coli is unable to produce pyrroloquinoline quinone (PQQ)[J]. Microbiology, 1997, 143(Pt 10): 3149-3156. |

| [88] |

张静, 刘孟粟, 秦志杰, 曾伟主, 周景文. 吡咯喹啉醌高产菌株选育及发酵优化[J]. 食品与发酵工业, 2022, 48(16): 56-64.

ZHANG J, LIU MS, QIN ZJ, ZENG WZ, ZHOU JW. Breeding and fermentation optimization of high titer pyrrorole-quinoline quinone strain[J]. Food and Fermentation Industries, 2022, 48(16): 56-64 (in Chinese). |

| [89] | URAKAMI T, YASHIMA K, KOBAYASHI H, YOSHIDA A, ITO-YOSHIDA C. Production of pyrroloquinoline quinone by using methanol-utilizing bacteria[J]. Applied and Environmental Microbiology, 1992, 58(12): 3970-3976. |

| [90] | LIU MS, YANG XW, REN Y, XIA HP, HUANG JZ, KE CR. Two-stage oxygen supply strategy for enhancing fed-batch production of pyrroloquinoline quinone in Hyphomicrobium denitrificans FJNU-6[J]. Applied Microbiology and Biotechnology, 2020, 104(15): 6615-6622. |

| [91] |

ZHAO ZG, ZHANG K. A method for producing pyrroloquinoline quinone through semi continuous fermentation process: CN109628509B[P]. 2022-05-10. 赵子刚, 张葵. 半连续发酵工艺生产吡咯喹啉醌的方法: CN109628509B[P]. 2022-05-10. |

| [92] |

MA K, YANG XP, SHI LJ, QIN TC, ZHONG GF, XU L, SU XX, WANG GL, DAI JS, ZHOU Y, WU ZZ, JIANG DK, CHENG YH. Method for separating and purifying pyrroloquinoline quinone by using supramolecular solvent extraction method: CN112358478B[P]. 2021-07-23 (in Chinese). 马科, 杨雪鹏, 史立军, 秦天苍, 钟桂芳, 徐琳, 苏筱渲, 王光路, 代军帅, 周颖, 吴贞贞, 蒋登科, 程源航. 一种利用超分子溶剂萃取法分离纯化吡咯喹啉醌的方法: CN112358478B[P]. 2021-07-23. |

| [93] |

YANG XP, MA K, ZHONG GF, HU XM, YE JB, SHAO H. Complex extraction method for separation and purification of pyrroloquinoline quinine in fermentation broth: CN104892597B[P]. 2016-05-04 (in Chinese). 杨雪鹏, 马科, 钟桂芳, 胡仙妹, 叶建斌, 邵化. 络合萃取法分离纯化发酵液中的吡咯喹啉醌: CN104892597B[P]. 2016-05-04. |

| [94] |

ZHAO Y, ZHANG K. Method for separating and purifying pyrroloquinoline quinone: CN111635402B[P]. 2021-04-30 (in Chinese). 赵燕, 张葵. 吡咯喹啉醌的分离纯化方法: CN111635402B[P]. 2021-04-30. |

| [95] |

ZHANG MH, JIANG YF, LAI QY, ZHAO ZG, CHEN L. Method for separating and purifying pyrroloquinoline quinone disodium salt based on fermentation liquid composite salting-out: CN109180674A[P]. 2019-01-11 (in Chinese). 张茂华, 蒋永飞, 赖庆云, 赵正国, 陈亮. 基于发酵液复合盐析的吡咯喹啉醌二钠盐分离纯化方法: CN109180674A[P]. 2019-01-11. |

| [96] |

MA K, YANG XP, ZHONG GF, WANG GL, WANG BY, HU XM, CHENG YH, SU ZY. Method for separating and purifying pyrroloquinoline quinone by using reverse micelle surface modified magnetic nano solid-phase extraction material: CN114146680A[P]. 2022-03-08 (in Chinese). 马科, 杨雪鹏, 钟桂芳, 王光路, 王冰洋, 胡仙妹, 程源航, 苏泽宇. 利用反胶束表面修饰的磁性纳米固相萃取材料分离纯化吡咯喹啉醌的方法: CN114146680A[P]. 2022-03-08. |

| [97] |

MA K, YANG XP, ZHONG GF, YE JB, CUI JZ, YAN J. Method for separating and purifying pyrroloquinoline quinone in fermentation liquid by molecularly imprinted solid-phase extraction method: CN106188042B[P]. 2018-01-05 (in Chinese). 马科, 杨雪鹏, 钟桂芳, 叶建斌, 崔君竹, 闫记. 采用分子印迹固相萃取法分离纯化发酵液中吡咯喹啉醌的方法: CN106188042B[P]. 2018-01-05. |

| [98] |

SUN R, LIU JM, REN M, ZHANG L. Method for extracting pyrroloquinoline quinone from fermentation liquor: CN111440167A[P]. 2020-07-24 (in Chinese). 孙荣, 刘建民, 任明, 张雷. 一种从发酵液中提取吡咯喹啉醌的方法: CN111440167A[P]. 2020-07-24. |

| [99] |

MA K, YANG XP, YE JB, ZHONG GF, WANG FF, YAN J, CUI JZ, HU XM, SHAO H. Ion pair dual water phase method for extracting and separating pyrroloquinoline quinone: CN105294687B[P]. 2016-11-16 (in Chinese). 马科, 杨雪鹏, 叶建斌, 钟桂芳, 汪芳芳, 闫记, 崔君竹, 胡仙妹, 邵化. 离子对双水相萃取分离吡咯喹啉醌的方法: CN105294687B[P]. 2016-11-16. |

| [100] |

ZHAO YF, WANG YS, WU B, CHENG H, XU N, MIN XR. Extraction method of pyrroquinolinequinone: CN1138776C[P]. 2004-02-18 (in Chinese). 赵永芳, 王银善, 吴波, 成汇, 徐宁, 闵向荣. 吡咯喹啉醌的提取方法: CN1138776C[P]. 2004-02-18. |

| [101] | KE CR, REN Y, GAO P, HAN J, TAO Y, HUANG JZ, YANG XW. Separation and purification of pyrroloquinoline quinone from fermentation broth by pretreatment coupled with macroporous resin adsorption[J]. Separation and Purification Technology, 2021, 257: 117962. |

| [102] |

YANG XP, MA K, HU XM, ZHONG GF, YE JB, LIU Y, MA GL. Method and application for producing pyrroloquinoline quinone by using Gluconobacter oxydans: CN104328155B[P]. 2019-06-28 (in Chinese). 杨雪鹏, 马科, 胡仙妹, 钟桂芳, 叶建斌, 刘寅, 马歌丽. 利用氧化葡萄糖杆菌生产吡咯喹啉醌的方法及应用: CN104328155B[P]. 2019-06-28. |

| [103] | van der MEER RA, GROEN BW, van KLEEF MA, FRANK J, JONGEJAN JA, DUINE JA. Isolation, preparation, and assay of pyrroloquinoline quinone[J]. Methods in Enzymology, 1990, 188: 260-283. |

| [104] |

LIANG XL, HAN CC. Hyphomicrobium LXL-PQ-409 and its application: CN110195032B[P]. 2020-09-22 (in Chinese). 梁新乐, 韩程程. 生丝微菌LXL-PQ-409及其应用: CN110195032B[P]. 2020-09-22. |

| [105] |

HOU ZP, CHEN F, JI YN, LIU P. Method for separating and purifying pyrroloquinoline quinone: CN112194658A[P]. 2021-01-08 (in Chinese). 侯争平, 陈锋, 吉毅楠, 刘培. 一种吡咯喹啉醌的分离纯化方法: CN112194658A[P]. 2021-01-08. |

| [106] |

HE YW, ZHAO Y, ZHANG K. Purification method of pyrroloquinoline quinone: CN110698472A[P]. 2020-01-17 (in Chinese). 何勇崴, 赵燕, 张葵. 一种吡咯喹啉醌的纯化方法: CN110698472A[P]. 2020-01-17. |

| [107] |

KE CR, HUANG JZ, YANG XW, REN Y, WEI J, LIAO C. Separation and purification method of pyrroloquinoline quinone in methylotrophic bacteria fermentation liquor and application of method: CN107056782B[P]. 2019-05-14 (in Chinese). 柯崇榕, 黄建忠, 杨欣伟, 任洋, 魏杰, 廖灿. 一种甲基营养菌发酵液中吡咯喹啉醌的分离纯化方法及其应用: CN107056782B[P]. 2019-05-14. |

| [108] |

GE X, ZHANG WC, XIONG XH. Method for eliminating side product polysaccharide in fermentation production of pyrroloquinoline quinone, and application of method: CN103361390B[P]. 2015-01-07 (in Chinese). 葛欣, 张惟材, 熊向华. 一种发酵生产吡咯喹啉醌过程中消除副产物多糖的方法及其应用: CN103361390B[P]. 2015-01-07. |

| [109] |

CHEN FC, ZHANG H, YE SH, CHEN YM, ZOU L. Denitrification hyphomicrobe and method for preparing pyrroloquinoline quinine by fermenting denitrification hyphomicrobe: CN115449499B[P]. 2023-03-24 (in Chinese). 陈辅辰, 张恒, 叶世豪, 陈誉民, 邹乐. 一种脱氮生丝微菌及其发酵制备吡咯喹啉醌的方法: CN115449499B[P]. 2023-03-24. |

2024, Vol. 64

2024, Vol. 64